UAC24

We at Unitop Aquacare Ltd. are offering Turnkey Solutions which helps our esteemed customers in reducing waste generation and optimizing energy. As a part of reducing waste and optimizing energy we have developed specialized coagulant called UAC24.

Effects of UAC24

- Separation of colloidal impurities such as Sizing, Fluffs etc from Weak Lye solution.

- Reduction of foam in weak lye solution resulting in stable pH.

- Reduces viscosity of the caustic lye.

Function of UAC24

It is observed that the weak lye coming from mercerizer contents impurities such as Starch, Sizes etc. These impurities can add scaling & fouling on Heat Exchangers used in Caustic Recovery Plant. Due to scales or precipitations of the particulate matter heat transfer efficiency of the heat exchanger reduces drastically which increases steam consumption and damages the tubes with in heat exchanger.

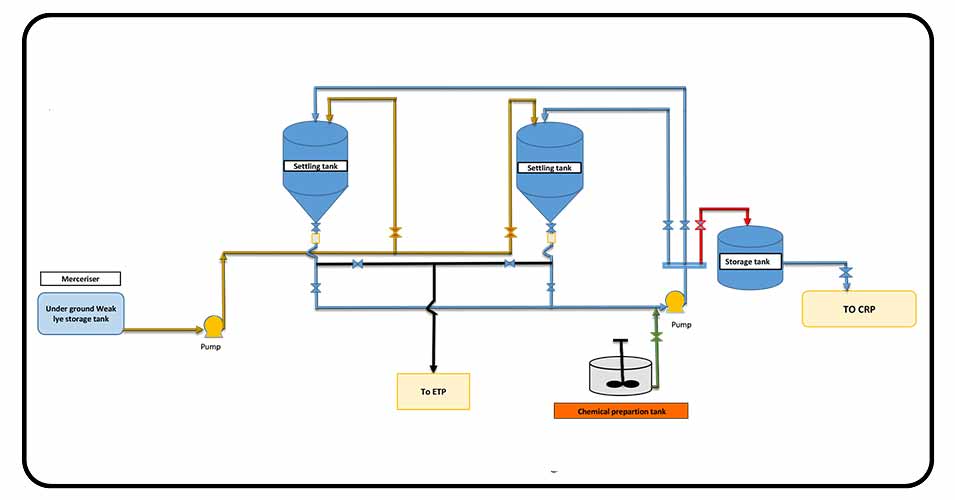

Considering the probable damages, it is essential to settle the impurities before it enters in heat exchanger. UAC24 is dosed in caustic lye. Coagulation takes place and Colloidal/Suspended impurities are settled in clarifier unit/settling tank. Supernatant is clear in nature and is then passed to Caustic Recovery Plant. Removal of foulants results in low energy consumption and increases life of Tubes in Heat exchanger.

Reduction in Maintenance due to UAC24:

- Reduction in Cleaning Frequency.

- Improved product capacity due to marginal reduction in shutdown and breakdown maintenance.

Effect on Operating Cost due to UAC24:

- Specific Gravity of the solution with Impurities is higher and hence it is difficult to identify the actual concentration of Caustic / Recovered Caustic. Due to uncertain Specific Gravity, more heating is provided during Caustic Recovery Operation, results in more Steam and Power. Due to reduction in Impurities Specific Gravity of the solution is normalized and hence overall steam required in Caustic Recovery is less. Reduction in Steam requirement results in savings on Power Cost.

- Effective reduction in quantity of H2O2 is observed after removal of impurities using UAC24.

- Effective reduction in fresh caustic due to efficient removal of Impurities from Caustic Solution.

Our installations

Download the Catalogue

Download our latest Water Technology Product Catalogue for valuable engineering insights, detailed product specifications, and key numbers to help with selecting and sizing pumps, filters, and other components. Our catalog is an essential resource for professionals in water management and treatment. Download your copy today and see the kind of insights and support that can help you succeed in your projects.