Resources of Unitop Aquacare

Unitop Aquacare is proud to rely on a strong foundation of manufacturing infrastructure, accompanied by a highly skilled project management team and a dedicated supply chain team. At the core of our operations lies the field of engineering, which serves as the backbone of our work. In fact, over 80% of our workforce comprises engineers from diverse disciplines such as chemical, mechanical, electrical, electronics, and automation.

The presence of these talented engineers allows us to tackle complex projects with confidence. Their expertise enables us to navigate and overcome challenges, even in the most demanding and difficult geographies around the globe. Through their collective efforts and proficiency, we ensure the seamless execution of projects, meeting deadlines and delivering exceptional results.

Our commitment to teamwork is unwavering, as it plays a pivotal role in our success. By fostering a collaborative environment, we encourage synergy among our employees, allowing them to complement each other’s strengths and work harmoniously towards a common goal. This collaborative spirit ensures that our projects are executed smoothly, efficiently, and with precision.

What we do?

Consistently prioritizing world-class quality, commitment, innovation, and service excellence, Unitop Aquacare aims to create and deliver superior value to its customers. These imperatives guide the company’s strategic decisions, operations, and overall approach to business, fostering strong customer relationships and positioning it as a trusted and reliable partner in the industry.

Manufacturing

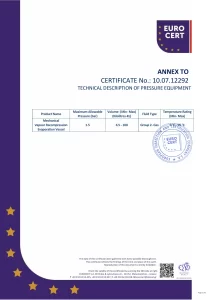

Unitop Aquacare takes pride in its world-class manufacturing infrastructure, which forms the backbone of our business lines. With three state-of-the-art manufacturing facilities located in India, we have the capacity to meet the most rigorous requirements of various countries, including CE, NR13, EAC, and SELO standards. Furthermore, all our facilities are ISO 9001:2015 certified, demonstrating our commitment to quality and excellence.

Factory 1: Located in Bhiwandi, an industrial hub within 45 km of Mumbai Airport, Unitop Aquacare’s Unit 1 encompasses a modern manufacturing setup spanning approximately 50,000 square feet. This facility is equipped with advanced machinery and technologies to ensure efficient production processes and maintain the highest standards of quality.

Factory 1

Factory 1: Located in Bhiwandi, an industrial hub within 45 km of Mumbai Airport, Unitop Aquacare’s Unit 1 encompasses a modern manufacturing setup spanning approximately 50,000 square feet. This facility is equipped with advanced machinery and technologies to ensure efficient production processes and maintain the highest standards of quality.

Factory 2

Factory 2: Unitop Aquacare’s Unit 2 is situated in Digha Village, another industrial hub within 45 km of Mumbai Airport. This facility boasts a modern manufacturing setup covering around 10,000 square feet. Here, we leverage cutting-edge manufacturing techniques to deliver top-notch equipment that meets the stringent requirements of our clients.

Factory 3

Factory 3: Unitop Aquacare’s largest manufacturing facility, Unit 3, is located in Umbargaon Valsad, Gujarat. Spanning an impressive 280,000 square feet, this facility is equipped with a modern manufacturing setup that enables us to handle large-scale production efficiently. With its expansive capabilities, Unit 3 plays a crucial role in meeting the growing demands of our clients, both domestically and internationally.

These manufacturing facilities, strategically located and equipped with advanced technologies, allow Unitop Aquacare to deliver superior products and solutions to our customers. Through our commitment to excellence and adherence to international standards, we ensure that our manufacturing processes consistently produce high-quality equipment for the aquaculture industry.

Engineering

At Unitop Aquacare, engineering serves as the backbone of our integrated offerings. We take pride in the fact that over 80% of our workforce comprises engineers from diverse disciplines such as mechanical, chemical, electrical, civil, and instrumentation, among others. This concentration of engineering talent allows us to provide comprehensive solutions and services to our clients.

Our engineering team possesses a wealth of knowledge and experience, and they leverage the latest design software and tools to ensure precision and efficiency in their work. They play a crucial role in facilitating seamless interfacing between various modules of an integrated plant, ensuring smooth operation and optimal performance.

With our global presence, we have gained expertise in various global codes and standards. This knowledge enables us to deliver projects that meet international requirements, ensuring compliance and reliability. Our engineering team stays up-to-date with the latest industry trends and best practices, allowing us to provide innovative solutions that meet the evolving needs of the aquaculture industry.

By combining technical expertise, cutting-edge design software, and a deep understanding of global codes and standards, our engineering team ensures that our integrated offerings are of the highest quality. We are committed to delivering excellence in every aspect of our work, and our engineering capabilities are at the forefront of achieving that goal.

Operations we perform.

Tube Expansion

Shot Blasting

Radial Drilling

Plate Rolling Machine

Plasma Cutting

MIG & TIG Welding

Dish Making Machine

Lathe Machine

Certificate of trust.

We are prestigious at engineering solutions for design & manufacturing across the continents from Asia to Europe.

U nitop Aquacare places a strong emphasis on delivering products and services of the highest quality. By maintaining stringent quality standards throughout its operations, the company ensures that its offerings meet or exceed customer expectations. This commitment to world-class quality is reflected in the certifications the company holds, such as ISO 9001:2015, which validate its adherence to robust quality management systems.

nitop Aquacare places a strong emphasis on delivering products and services of the highest quality. By maintaining stringent quality standards throughout its operations, the company ensures that its offerings meet or exceed customer expectations. This commitment to world-class quality is reflected in the certifications the company holds, such as ISO 9001:2015, which validate its adherence to robust quality management systems.

Unitop Aquacare is deeply committed to its customers, understanding that their success is integral to its own success. The company prioritizes building enduring relationships with its clients, based on trust, reliability, and mutual growth. This commitment extends to providing personalized attention, understanding customer needs, and delivering solutions that meet specific requirements.

Unitop Aquacare is deeply committed to its customers, understanding that their success is integral to its own success. The company prioritizes building enduring relationships with its clients, based on trust, reliability, and mutual growth. This commitment extends to providing personalized attention, understanding customer needs, and delivering solutions that meet specific requirements.

Unitop Aquacare believes in the power of innovation to drive progress and deliver value. The company continuously seeks innovative solutions and technologies to improve its products and services. By staying at the forefront of industry advancements, Unitop Aquacare can offer cutting-edge solutions that address evolving customer needs and provide a competitive edge.

Unitop Aquacare believes in the power of innovation to drive progress and deliver value. The company continuously seeks innovative solutions and technologies to improve its products and services. By staying at the forefront of industry advancements, Unitop Aquacare can offer cutting-edge solutions that address evolving customer needs and provide a competitive edge.

Service excellence is a cornerstone of Unitop Aquacare’s business philosophy. The company strives to provide exceptional service at every stage of the customer journey. From initial consultation and project design to installation, commissioning, and after-sales support, Unitop Aquacare is committed to exceeding customer expectations. The company’s dedicated engineering team and customer support staff ensure timely and effective assistance, fostering long-term customer satisfaction.

Service excellence is a cornerstone of Unitop Aquacare’s business philosophy. The company strives to provide exceptional service at every stage of the customer journey. From initial consultation and project design to installation, commissioning, and after-sales support, Unitop Aquacare is committed to exceeding customer expectations. The company’s dedicated engineering team and customer support staff ensure timely and effective assistance, fostering long-term customer satisfaction.

Engineering is the backbone of Unitop’s offerings. More than 70% of the employee strength consists of engineers of various disciplines – mechanical, chemical, electrical, civil, Instrumentation etc. Knowledge and experience coupled with the latest design software, engineering team ensures accuracy and smooth interfacing between various modules of an integrated plant. With global presence, comes the expertise in various global codes and standards.

Engineering is the backbone of Unitop’s offerings. More than 70% of the employee strength consists of engineers of various disciplines – mechanical, chemical, electrical, civil, Instrumentation etc. Knowledge and experience coupled with the latest design software, engineering team ensures accuracy and smooth interfacing between various modules of an integrated plant. With global presence, comes the expertise in various global codes and standards.

A strong backbone of SCM team supports the complexities involved in Praj’s business. With around 50 qualified professionals, the team handles procurement of over 100 categories of commodities, metals, equipment, electrical, automation, piping, structural, rotary equipment like pumps and compressors.

A strong backbone of SCM team supports the complexities involved in Praj’s business. With around 50 qualified professionals, the team handles procurement of over 100 categories of commodities, metals, equipment, electrical, automation, piping, structural, rotary equipment like pumps and compressors.

With the goal of providing environment-friendly solutions for a future perfect world, Unitop established Matrix-R&D center in the very first decade of its inception, Unitop Matrix is the common innovation engine for all business units of Unitop Industries. Each business unit strives to stay ahead of competition through continuous Investment in cutting-edge technology & product research carried out at Unitop Matric

With the goal of providing environment-friendly solutions for a future perfect world, Unitop established Matrix-R&D center in the very first decade of its inception, Unitop Matrix is the common innovation engine for all business units of Unitop Industries. Each business unit strives to stay ahead of competition through continuous Investment in cutting-edge technology & product research carried out at Unitop Matric

Our vision is to become a world-class O&M Company supplying process equipment and providing service for utilities keeping safety and compliance as the bedrock of our services. We can remotely monitor and manage your plants with the benefits of Increased site availability and reduced downtime. This maximizes profitability, revenues, and energy production. We provide customized solutions with optimized KPIs to fit your business strategy and operating profile. We offer our services to distillery plants globally.

Our vision is to become a world-class O&M Company supplying process equipment and providing service for utilities keeping safety and compliance as the bedrock of our services. We can remotely monitor and manage your plants with the benefits of Increased site availability and reduced downtime. This maximizes profitability, revenues, and energy production. We provide customized solutions with optimized KPIs to fit your business strategy and operating profile. We offer our services to distillery plants globally.

Unitop’s project management team consists of qualified, experienced and PMI certified professionals well versed with the global standards and practices.

Unitop’s project management team consists of qualified, experienced and PMI certified professionals well versed with the global standards and practices.

A strong backbone of SCM team supports the complexities Involved in our business. With around 50 qualified professionals, the team handles procurement of over 100 categories of commodities, metals, equipment, electrical, automation, piping, structural, rotary equipment like pumps and compressors.

A strong backbone of SCM team supports the complexities Involved in our business. With around 50 qualified professionals, the team handles procurement of over 100 categories of commodities, metals, equipment, electrical, automation, piping, structural, rotary equipment like pumps and compressors.

Unitop’s business lines are supported by its world-class manufacturing Infrastructure. Unitop has 4 manufacturing facilities in India. All the facilities have the capability to manufacture equipment in compliance with the most stringent requirements of various countries viz. CE, EN, DOSH, MOM, GOST-TR. The facilities are also ISO 9001: 2015 and ASME (U, U2, R, H, S) certified.

The dedicated manufacturing facility consisting of two separate workshops for carbon steel and stainless steel fabrication is located at Kandia Special Economic Zone in Gujarat on the western coast of India. This SEZ facility is right at Kandia port, facilitating speedy and hassle free delivery. The other two manufacturing facilities are well connected to ports through national highways.